Hot-dip Galvanized Battery Cage System for Laying Hens in Poultry

Farm Housing

management

The layer chicken cage

Cage-raised chickens are housed in cages, restricting their ability

to choose environmental conditions and depending solely on humans

to provide suitable conditions for survival and production. Hence,

cage-raised chickens require advanced feeding and management

techniques.

Cage rearing is the predominant three-dimensional method for

raising chickens and is widely used for off-ground production. More

than 80% of laying hens in developed countries are housed in cages.

In China, cage rearing has gained popularity and shown promising

results due to improvements in cage materials and structures. It is

recognized as the future direction for commercial production of

laying hens, chicks, breeders, and broilers, offering significant

advantages over traditional floor rearing methods.

In cages, a higher density of chickens per unit area means

substantial savings on housing and land compared to floor rearing.

Cages are utilized to isolate chickens and prevent epidemic

outbreaks.

Cage systems streamline management tasks, saving labor and

improving productivity.

Controlled environmental conditions in cages promote uniform

growth, high and stable egg production rates.

Observation and removal of unhealthy chickens in cages ensures the

health and productivity of the flock.

Reduced ground contact in cages minimizes parasitic diseases and

lowers medication costs. Elimination of bedding material saves

expenses.

Maintaining clean and hygienic conditions in chicken houses

enhances product quality by preventing egg contamination due to

feces.

Limiting chicken activity in cages reduces feed consumption,

increases feed conversion efficiency, and improves economic

outcomes.

Cage systems make it straightforward to collect chicken manure,

which can be used effectively as feed for pigs and fish after

fermentation.

Enhancements in feeding management and advancements in cage

materials can address issues such as nutritional deficiencies,

fatty liver syndrome, egg-laying fatigue, chest cysts, brittle

bones, and flexible bones in cage-raised chickens to varying

degrees.

Multi-layer coops can promote the health of chickens

Poultry farmers often struggle to achieve healthy outcomes in

chicken rearing due to their negligence in utilizing multi-layer

coops. These coops are pivotal in maintaining chicken health and

boosting reproductive efficiency.

Unlike a standard wire cage equipped with a metal mesh floor and

heating elements, a well-designed multi-layer chicken coop serves a

different purpose. Its wire flooring is engineered to promote

efficient fecal removal, reducing waste accumulation around the

flock and mitigating the risk of fecal-borne diseases. This

proactive design supports chicken health and protects farmers'

interests effectively.

Increase egg production

The productivity of chickens is closely tied to their health, and

providing enrichment cages can greatly enhance their egg production

capacity.

It's been estimated that 60% of eggs used in products such as

mayonnaise, sandwiches, and cakes originate from caged chickens,

highlighting the preference for multi-layer cage systems to

optimize egg production

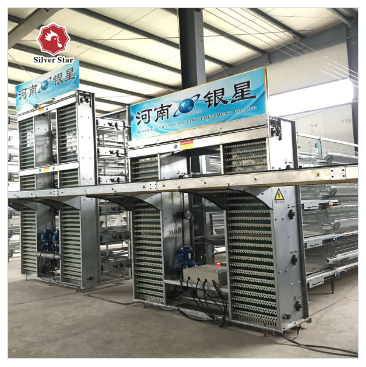

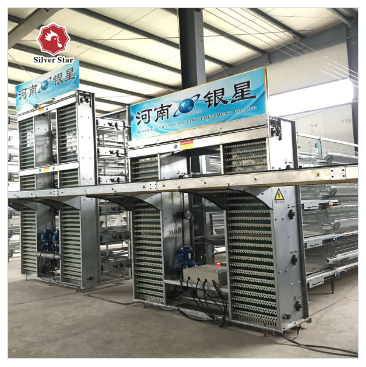

Product introduction

Henan silver star cage net introduction, 1250 type frame layer

layer cage, scope of application: laying hens, breeding hens. Each

cage net 650 mm long, 1250 mm wide, each cage net around a door,

each door 650 mm long, 650 mm deep, 500 mm high. Large open space

for maximum comfort, precise structural details to enhance welfare,

up to 9 animals per door. The chicken has an area of 452 square

centimeters. Each cage net feeding capacity of 18.

The breeding capacity of each compartment of three layers is 54.

The breeding capacity of each enclosure is 72. The breeding

capacity of each enclosure is 90. There are 108 birds in each

enclosure of six floors. Four layers are the most common.

Multilayer partition structure optional, duplex multilayer

structure generally to take 4 plus 4 eight layers, or 3 plus 3 plus

3 nine layers. Reduce housing costs. Improve the overall value. To

learn more about related products, matching related automatic

equipment welcome to inquire

| 3-tiers | 0.65*1.25*2.65 m | 54 chickens |

| 4-tiers | 0.65*1.25*3.3 m | 72 chickens |

| 5-tiers | 0.65*1.25*4.6 m | 90 chickens |

| 6-tiers | 0.65*1.25*4.9 m | 108 chicekns |

| 7-tiers | 0.65*1.25*5.5 m | 126 chickens |

| 8-tiers | 0.65*1.25*6.2 m | 144 chickens |

| 9-tiers | 0.65*1.25*7.2 m | 162 chickens |